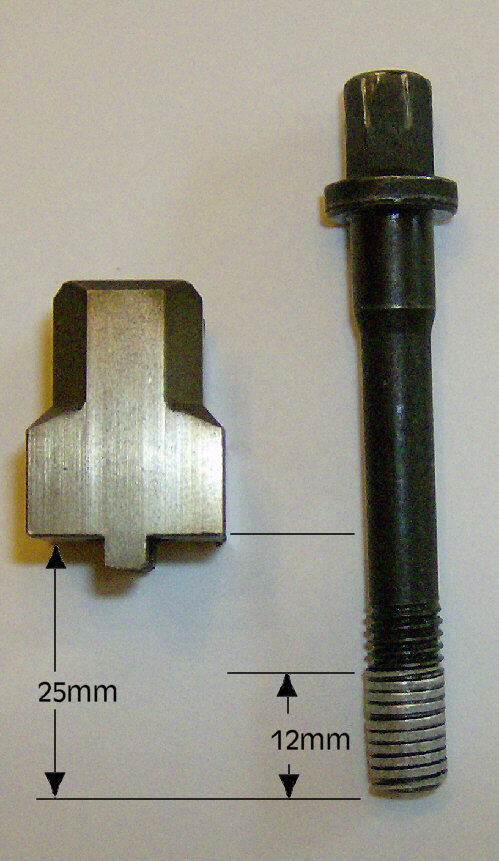

P/N 1015CORE

This tooling has been used in rocker arm thread repair

where the threads must start a few millimeters deep below a “Slot”.

The core drill countersink combination will have to set by hand.

We use this special 4 flute core drill because it makes drilling

thru a slot easy. Using a traditional 2 flute is difficult because the drill

it wants to hang on the slot and break.

Rocker arm support can be GM style 3100 and 3400 models along with Buick and others.

The insert must be below the notched portion of the support.

so our standard repair kit for the M10x1.5 will not work.

The special 4 flute core drill included will cut thru the notched

area without difficultly. A standard 2 flute drill would hang on the sides.