PROBLEM FORD HEADS ROMEO STYLE

RF-1L2E or RF-2C5E have a step.

Check the casting number if your vehicle is 2001 and newer.

If your vehicle is 2000 or earlier you do not have a step in your head

just skip the counterbore tool p/n 55518 and start with the reamer tool.

If you are repairing a RF-1L2E or RF-2C5E head, this is a Romeo 2001 and up PI head. Due to a countersink problem with the head design, a special counterbore tool P/N 55518 is needed to give the hole clearance for the repair.

Checking Casting number and location:

The most important part in the above casting number is the second set of digits 1L2E.

Location of casting number: This Casting number can be found just above the

exhaust manifold.

If you use a digital camera or cell phone camera and take a picture you will see the image correctly.

If looking down from the passenger side it should be located just below the oil dip stick.

If looking down from the driver side it should be located further back near the firewall.

If you use a mirror to see it from the top view note that the number will appear backwards.

You are just looking for the RF-1L2E start of the casting number.

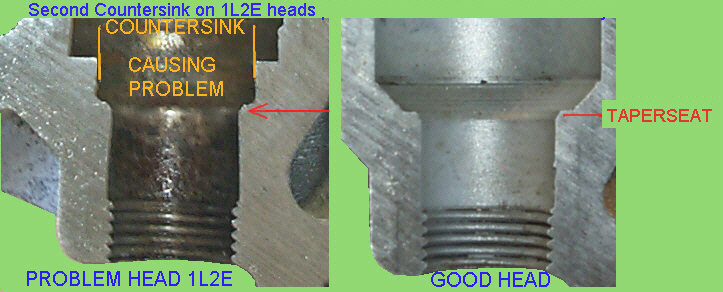

Below is a Section view of problem:

The left picture “problem head 1L2E” will not allow the reamer to the correct location.

The p/n 5553 kit includes a counterbore that will prepair the hole by cutting out the “extra step” of aluminum

not present in other ford heads.

The counterbore p/n 55518 is a self guiding tool that has a pilot shank with 45 degree stop just before the 4 cutting teeth. The counterbore will cut out the extra material found in the FORD 1L2E heads and will stop at the correct depth by stopping on the original OEM taper seat in the

Note: Previously repaired hole by a helicoil or save-a-thread .660 on the O.D.

If you need to repair a Ford 2001 and up Romeo RF-1L2E style head that was previously repaired the original taper seat has been removed and the p/n 55518 counterbore will not have the OEM original taper to stop on.

CounterBoring Manually with head on vehicle.

You must countersink manually by hand without removing the head 5/16 to 3/8 of an inch. You will have to place the counterbore in the hole then mark the “wrench” to visually go down 5/16 to 3/8 of an inch to remove the step of aluminum found in these heads, then continue the steps starting with the reamer.

Now continue with the p/n 5553 repair kit and the insert will be in the correct location.